Before you start purchasing optics coating, there are some things you need to know about reliable optical liquids. These include Quick coating applications, Low contact angles, Concave and convex surfaces, and storage containers.

Read on and search for laboratory services custom blend liquids Essex County NJ to learn more. This article will give you a basic overview of optical coatings and how they can improve your business. Then, you can use this information to choose the right optics coating solution for your needs.

Quick Coating Application

When applying a fast-curing optical liquid coating, the first step is ensuring that the optic is clean. During the coating process, tissue paper should be soaked in acetone or alcohol before applying it to the optic. This prevents the risk of scratching the surface.

This method is beneficial when coating small optics. However, it is not recommended for cemented optics. The liquid you choose will depend on the hardness and durability of the optic. You can find a variety of these on Zoro.com along with other industrial supplies.

Optical liquids and emulsions can be used in wet and dry processes. The presence of a coating material ensures that it will be applied precisely and consistently. Optical liquids, such as silicone, can provide a high degree of control over the process. These liquids are easy to work with and can be a good choice for a wide range of optical applications.

Low Contact Angle

The measurement of low contact angle accuracy when using reliable optical liquids depends on several factors. The first is the capillary length of the liquid. This factor can affect the macroscopic contact angle. Generally, a lens’s magnification is inversely proportional to the capillary size. However, there are exceptions to this rule.

One example is superoleophobic SiO2 surfaces, which have lower pitches. This lowers the measurement accuracy. Another reason for the low contact angle is incorrect contact point determination. Although the inaccuracy is negligible, in some cases, it could cause 1deg of offset for 5 pixels. The inaccuracy can reach ten degrees if the lens magnification is too high.

Large contact angles are difficult to measure because of the limited resolution near the contact line and the image analysis algorithm. Moreover, they may approach 180 degrees. Therefore, a low contact angle should be considered when using super-repellent liquids.

However, large apparent contact angles should not be interpreted as low contact angles. Instead, they should be considered local and temporary contact angles. If a low contact angle is reported for a liquid, it could be because the capillary length is too small, or it is an anomaly.

Concave and Convex Surfaces

A lens can have both convex and concave surfaces when using reliable optical liquids. These surfaces are created by combining two sheets of a thermoplastic material that are light-transmitting. These two sheets are then moved into a pressure-applying relationship. The resulting optical lens will be shaped according to the prescribed power. The lens can be used for eyeglass frames and other optical apparatus.

In photonics, both concave and convex surfaces are standard. Therefore, both surfaces require testing methods and materials to ensure they are clean. One method to evaluate the cleanliness of convex surfaces is by using contact angles.

This measurement method allows for extreme accuracy. It also compensates for surface variation. For example, if the surface is concave, the lens may have a larger contact angle with the light source.

Storage Containers

Suppose you’re in the business of producing optical materials and are looking for reliable storage for your products. In that case, Safe-Guard offers you a wide range of optics containers that can be customized to fit your exact specifications.

Not only is this system cost-effective, but it also pays dividends in immediate loss reduction. These containers are easy to stack and have snap-on lids. They’re also translucent, so they’re easy to use and see.

PET-G optics packaging containers are the industry standard for storing and shipping optical materials. They eliminate the need for lens paper or foam liners and offer superior crush protection. Made of high-quality PET-G material, Safe-Guard containers are ideal for various applications and are NASA-tested. They also enhance the presentation of your products. The following is a list of the benefits of using Safe-Guard containers:

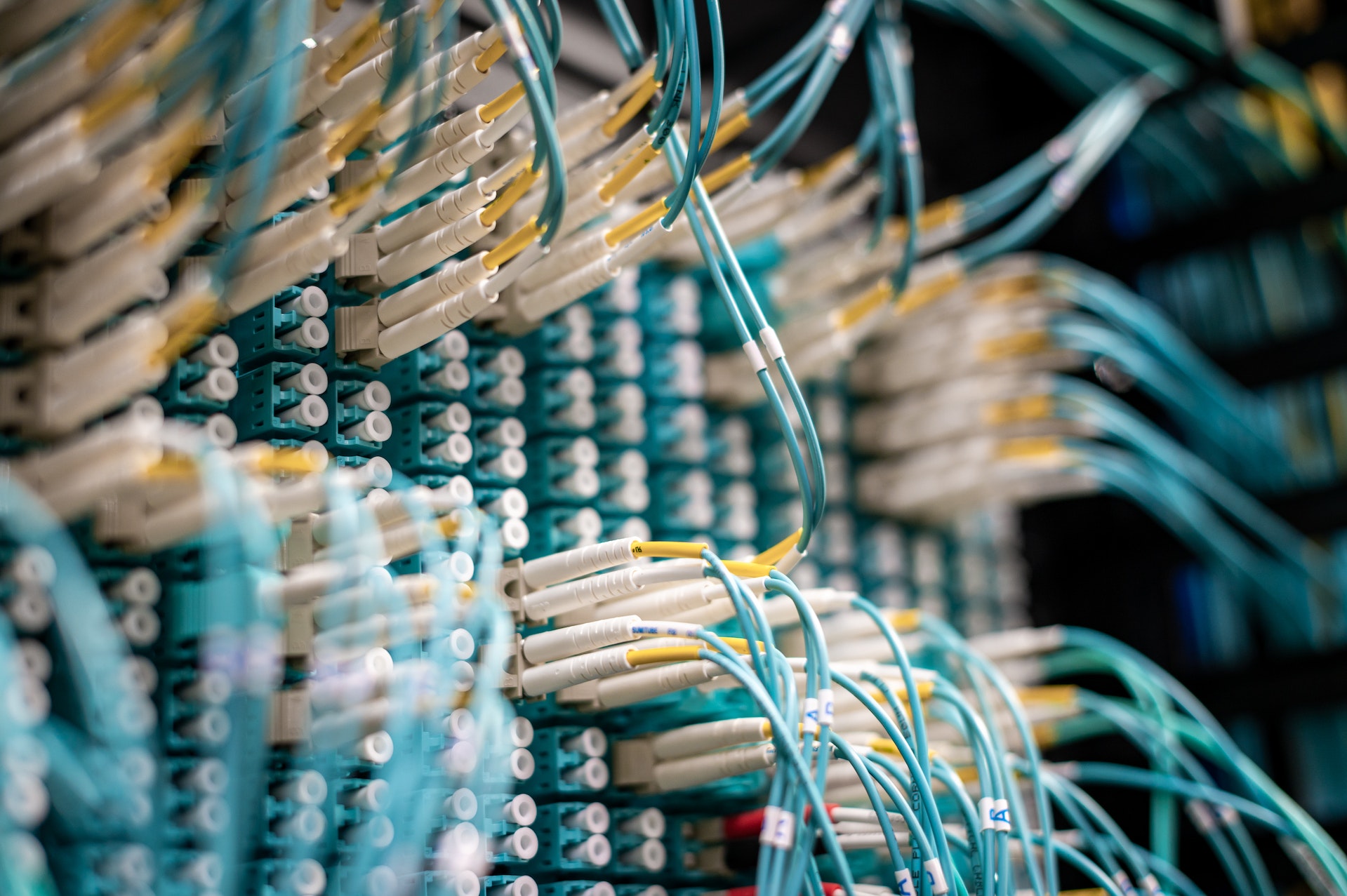

Cleaning Fiber-Optic End-Faces

Reliable optical liquids are essential for cleaning fiber-optic end faces. However, IPA is not a suitable solvent for fiber-optic connections and will not remove soil from them. IPA is also not ideal for cleaning buffer gels or oils. Moreover, IPA tends to leave a residue. Hence, it is essential to use optical-grade wipes. These wipes are available in sealed packages to avoid contamination.

The naked eye cannot see end-face contamination. Therefore, the microscopic dust particles and fingerprint oils must be viewed with specialized scopes. This inspection is necessary before the medical provider connects a fiber-optic instrument. Repeating the examination until the end face is clean is essential. Cleaning the fiber-optic end faces crucial to ensure the reliability of the device.